experienced heat treater On call

Heat treating is an essential part of the manufacturing process for most products. Different heat treating processes are available to accomplish various purposes such as strengthening, stress relieving, surface hardening, and microstructural modification. At Pendley Consulting, we know heat treating in and out. Our experience includes managing a commercial heat treating firm, directing in-house heat treating for major OEM’s, and working with third-party heat treating companies.

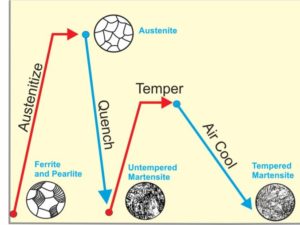

Whether your heat treating is done in-house or at a commercial heat treater, our technical support can help ensure that the end results meet your expectations. We have extensive experience in all common heat treating practices including hardening (quench-and-temper), normalizing, annealing, stress-relieving, age hardening, carburizing, nitriding, boronizing, and vacuum heat treating.

We can provide technical support in the form of troubleshooting heat treating processes, writing heat treating procedures, conducting analysis of heat treated parts, interacting with customers and vendors, and more.

Optimize your heat treating results! Click below to contact us today.